ANTONINIANII FROM THE MINT OF ANTIOCH UNDER THE REIGN OF PHILIP THE ARAB (244-249 AD) |

HOME |

COIN |

HISTORICAL AND |

CLASSIFICATION |

BUST STYLES AND |

NUMBER OF |

CARPIC CAMPAIGN |

MY |

LINKS |

The coin striking process remains a poorly known topic, especially for collectors who are often much more interested in coins themselves rather than the way they were produced. Thatís why I decided to include this chapter to show that numismatic science is not only about gathering coins...

A mint in the Roman Empire is generally seen as a building gathering all minting steps, from crude metal to finished coin. The organization must have been very well defined there because efficiency was a very significant factor : until the mid IIIrd century the large majority of the imperial coins was produced by the mint of Rome which had to ensure all by itself the supply of currencies for the whole Empire.

It is not certain that this operation was carried inside the mint. Indeed, the Imperial Treasure was kept in many cities of the Empire, often away from the minting city, and monetary blanks (metal disc constituting the "body" of a coin) were probably produced there and then brought under good escort to the mint.

Blanks production gathers three different operations : metal casting, alloy preparation and the manufacture of blanks. Metal casting was carried out starting from the newly extracted ore and probably included old issues as well, thus making it possible to renew the monetary stock in circulation (letís not forget that it was the weight of noble metal contained in the coin that made its value, thatís why certain coins were still in circulation several decades after their issue).

The following step was alloy preparation by addition of other metals since precious metal was not to be used pure (Antoninianii are made of billon, alloy of copper and silver). Finally the monetary blanks manufacture consisted of casting metal in individual moulds. As it was already mentioned, the value of a coin was determined by its noble metal weight and so the founder had to come up with a well defined number of blanks for a specific metal weight : under the reign of Philip the Arab, the weight of an antoninianus was 1/72 of the Roman Pound, which means the average weight was about 4.51g per specimen, and had to be included between upper and lower limits defined by the administration. One can easily understand then that it was in the founderís interest to get as closer as possible to the lower limit in order to maximize his personal profit.

Each mint had its own engravers; if the engraving style is quite uniform for the mint of Rome, we can notice that it is not the case for the mint of Antioch whose engraving quality is rather variable and was obviously the work of several more or less skilful engravers.

Monetary dies, in bronze or iron, were crafted one at a time, carved by hand using a punch, thus explaining why dies are all different. Contrary to the mint of Rome, which only represented Philipís bust radiate, cuirassed and draped turned right, seen from behind, the engravers from the mint of Antioch took freedom to represent the Emperor bust in various positions : turned right or left, seen from front or from behind, cuirassed & draped or only cuirassed. In fact, those are the same busts that were represented on tetradrachms from Antioch.

The steps for the die engraving process are unknown but according to my observations they could have been the following : first the engraver carried out the border of dots of about 19 to 20 mm diameter, then carved a very light circular mark, almost invisible, allowing him to locate the jambs site of the letters constituting the legend (such marks are often obversed on antoninianii of Philip from Antioch, see example below). Then he engraved the representation inside this mark, for example a divinity on a reverse die, and added the legend whose letters could possibly be displaced if the representation exceeded preset area.

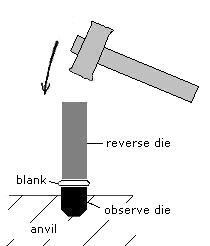

Each mint was divided into several small workshops called "officinas", each one of them striking a different reverse. Antoninianii, coins of small diameter and manufactured from a rather soft metal were hammer struck while large bronzes or Greco-Roman tetradrachms which required significantly more force were minted with the help of a machine constituted of a mass slipping between two rails that struck the reverse die which was held over the blank using grips.

During hammer striking, the obverse die -representing the Emperor bust and shaped as a truncated cone- was enchased in an anvil. The blank was placed on this obverse die and then the reverse die hold with the hand was placed on top of the blank. Only one blow of heavy hammer with the other hand was enough to "print" the image on the blank. For metal distribution reasons during striking, die positions were always 6h or 12h. We do not know if striking was carried out on hot or cold blanks.

Hammer striking was a very fast operation, probably a few seconds by coin. In order to achieve such throughput, two or three people must have participated : a first worker deposited a blank on the die then a second one struck the coin, which was then withdrawn by a third worker. It is in fact difficult to picture the worker who struck the coins placing the dies each time... However it is conceivable that the worker who positioned the blanks and the dies could withdraw the coins with the other hand (if coin striking was carried out on cold blanks).

Obviously the reverse dies absorbed most of the energy during striking and therefore deteriorated faster, broke more often and got replaced more frequently than the obverse die. This explains why coins can have the same obverse but different reverses and vice-versa : the study of die-links is based on this phenomenon. This study concerning antoninianii from Antioch remains rather complex due to the variety of busts represented on them and to the scarcity of these coins.

Although it was considered as a very serious crime in the Roman Empire, forgery was rather common. It consisted of covering a copper blank with thin silver foil and then striking it, giving it the appearance of a normal coin (the resulting coin is called a "fourree antoninianus"). The forger obtained a significant profit since the forged coin had the same commercial value as an official coin, while containing very little noble metal weight.

However, there are various categories of fourree within the antoninianii :

- Local issues & barbaric imitations : they were stuck by small local mints and were intended for a local use. Those coins were probably tolerated by Roman administration in some geographical areas where quantity of official coins in circulation was insufficient. These coins are easily recognizable : the engraving style is generally poor and legends sometimes donít have any significance. Moreover, sometimes neither the mint of Rome nor the one of Antioch had used those reverses on coins representing that Emperor.

- Imitations intended to fool Roman citizens : these coins are identical to the official types, but the engraving quality is generally worse. These coins were difficult to locate at that time but are now much easier to identify because the silver layer is often "scaled" and the copper has begun to show.

- Imitations made with official dies : they look like the ones on the previous category, but were manufactured using official dies coming from the mint of Rome or Antioch. These coins were perhaps manufactured by the mint workers themselves or by forgers who would have stolen the dies from the mint. To avoid any risk of theft, the dies were collected at the end of the day and were redistributed to the workers every morning. This could also explain the existence of hybrid coins from the mint of Rome that associate, for example, a bust of Philip II with a reverse of Otacilia Severa.

< previous page |

- EMAIL ME - |

next page > |